Overcoming Challenges in Production Hiring through Production Assessment Tests

Key Takeaways

Production assessment tests provide a structured, objective way to evaluate manufacturing candidates based on real-world abilities rather than relying solely on resumes or interviews.

These tests play a crucial role in improving safety, productivity, and quality by ensuring only capable and well-trained individuals operate machinery and handle production tasks.

Manufacturing assessment tests help organizations identify training needs, reduce onboarding time, and build reliable, high-performing production teams.

Platforms like Skillrobo offer customizable assessment templates, automated scoring, and analytics dashboards that streamline the entire production testing process.

Introduction

In manufacturing and production environments, the workforce determines how well an organization can deliver on quality, efficiency, and safety. With production lines becoming more complex due to automation, sensors, machine controls, and digital tools, companies cannot afford to hire workers whose skills are mismatched or insufficient. Traditional hiring methods fall short because they are more focused on evaluating technical skills alone.

You need candidate evaluation tools that provide comprehensive assessment of communication skills, personality traits, technical precision, mechanical aptitude, and safety awareness. This is where production assessment tests become indispensable, providing a systematic way to measure the exact competencies required for production roles.

Production assessment tests bring clarity and structure to the hiring process by simulating real production activities or evaluating the knowledge needed to perform them. Instead of relying on assumptions, employers gain a fact-based picture of how applicants think, respond, and perform under production-like conditions. These tests also help reduce onboarding friction, minimize errors during early training stages, and ensure that new hires integrate seamlessly into production workflows. As manufacturing industries continue to adopt advanced robotics, digital dashboards, and automated workflows, the need for a skilled, dependable workforce becomes stronger each year.

Production assessment tests are not just screening tools; they are strategic enablers for workforce planning, performance improvement, and operational reliability. This expanded guide covers what production testing is, why it matters, the types of assessments available, deep-dive benefits, expanded use cases, and how Skillrobo enhances the process with automation and analytics.

What Is Production Testing?

Production testing, or a production assessment test, refers to evaluating a candidate’s or employee’s ability to perform manufacturing and production tasks accurately and safely. These tests measure applied skills such as machinery handling, adherence to SOPs, quality checks, equipment troubleshooting, production speed, and safety awareness. Unlike generic aptitude tests, production testing mirrors real factory conditions, helping employers understand how individuals behave in hands-on environments.

These assessments may include performance simulations, digital knowledge tests, hands-on assembly tasks, skill-based scenario evaluations, and mechanical aptitude checks. The core objective is to determine whether a candidate can maintain the precision, consistency, and discipline required on the production floor. For example, production operator assessment tests often measure an applicant’s ability to detect defects, interpret work orders, document production data, or handle repetitive tasks without loss of quality.

Organizations rely on production tests not only for hiring but also for training evaluation, role progression, and competency benchmarking. This structured assessment approach helps ensure that workforce skills stay aligned with the evolving demands of modern manufacturing.

Challenges in Manual Hiring for Production Roles

Hiring for production roles has always been complex, but the challenges become significantly more difficult when organizations rely on manual, traditional hiring practices. Unlike corporate or administrative roles where interviews and resumes offer a fair amount of insight, production roles demand precision, discipline, consistency, and safety-driven behavior. These qualities cannot be reliably identified through conversation alone. Manual hiring introduces inconsistencies, biases, longer hiring cycles, and unexpected workforce issues that directly affect operational performance. The challenges are amplified in fast-paced manufacturing environments where workforce shortages, shift-based roles, and high production targets require reliable and job-ready employees from day one.

One of the most common challenges in manual hiring is the over-reliance on resumes. Production candidates often present minimal or generic resumes that do not accurately reflect their hands-on capabilities. A resume might mention machine operation or quality inspection experience, but it cannot convey the candidate’s actual skill level, their consistency under pressure, or their safety awareness. Hiring teams end up making assumptions that may not translate into real performance on the shop floor, leading to poor job matches and higher turnover rates.

Another significant challenge is inconsistent interviews. In manual hiring processes, interviews depend heavily on the hiring manager’s personal judgment, experience, and interviewing style. One manager may prioritize punctuality and communication, while another may focus more on technical knowledge. This lack of standardization leads to unpredictable outcomes. Candidates who interview well may underperform in real production tasks, while those with weaker communication skills but excellent technical abilities may get overlooked. These inconsistencies make it difficult for organizations to build reliable production teams.

Manual hiring also struggles with accurately assessing safety competencies. Production environments are governed by strict safety protocols, yet traditional interviews rarely explore safety scenarios in depth. Asking a candidate whether they have worked safely in the past does not reveal their ability to identify hazards, respond to alarms, or follow lockout-tagout procedures. Without a structured testing mechanism, organizations risk hiring individuals who may unknowingly pose safety hazards to themselves and their teammates. The consequences can range from minor incidents to severe workplace accidents that disrupt production and lead to legal complications.

Time-to-hire is another major challenge. Production roles often have urgent staffing needs due to shift rotations, sudden demand spikes, or workforce turnover. Manual hiring involves multiple steps such as resume screening, phone interviews, in-person discussions, and manual assessment exercises, all of which take days or even weeks to complete. During this time, production lines may operate understaffed, placing additional pressure on existing workers and lowering overall productivity. Extended hiring cycles directly impact production targets, delivery commitments, and operational efficiency.

A lack of scalability makes manual hiring even more problematic. When manufacturers need to hire for large production batches, expand to new locations, or increase output during peak seasons, manual processes simply cannot keep up. Hiring teams get overwhelmed, internal communication breaks down, and candidate evaluation becomes rushed, increasing the risk of errors. In industries where speed and efficiency define competitiveness, manual hiring bottlenecks can slow down growth and result in costly staffing shortages.

Bias is another hidden challenge in traditional hiring. Without standardized assessments, hiring managers may unintentionally favor candidates based on communication style, personality, or background rather than actual skill. This not only results in unfair hiring practices but also prevents skilled workers from being recognized. Production roles demand objectivity, and manual hiring often lacks the tools to ensure fair and consistent evaluation for every applicant.

Finally, manual hiring provides limited insight into long-term potential. Without structured testing or data-driven evaluation, organizations cannot predict how well a candidate will adapt to new machinery, learn new processes, or handle evolving production standards. This lack of foresight affects succession planning, multi-skill training programs, and leadership development pipelines, ultimately hindering workforce growth and resilience.

These challenges highlight why manufacturing companies are shifting toward automated production assessment tests and digital workforce evaluation tools. By adopting structured testing platforms like Skillrobo, organizations can overcome the limitations of manual hiring with accuracy, consistency, and speed. Automation ensures that every candidate is evaluated fairly, objectively, and based on the exact skills required for production success.

Why Production Assessment Tests Matter in Manufacturing

Manufacturing environments require accuracy, teamwork, discipline, and fast decision-making. When an unqualified worker operates machinery, the consequences range from increased scrap rates to serious safety incidents. Production assessment tests help mitigate these risks by ensuring that every hire meets minimum technical and safety competencies before stepping onto the shop floor.

These tests also play a vital role as industries adopt new technologies like smart machines, industrial IoT, RFID-based systems, and automated production lines. Employees need digital literacy, machine monitoring skills, and the ability to respond to alerts or deviations. Production testing helps identify talent who can adapt quickly to evolving production methods and handle both manual and automated tasks.

Beyond performance and safety, production assessment tests support workforce planning and operational consistency. By evaluating employee skills regularly, organizations can identify training gaps, rotate workers intelligently between stations, and build multi-skilled teams capable of handling peak loads and shift changes. In environments where downtime directly affects revenue, these tests help maintain continuity, reduce errors, and ensure regulatory compliance.

Types of Production Assessment Tests

Technical Skills Tests

Technical production tests evaluate mechanical aptitude, familiarity with tools, ability to read diagrams, understanding of production processes, and basic equipment troubleshooting. Candidates may interpret assembly drawings, identify machine components, or demonstrate knowledge of automated systems. These tests are essential for roles involving machine setup, line operation, or basic maintenance tasks.

Cognitive and Problem-Solving Tests

Cognitive tests assess logical reasoning, spatial ability, pattern recognition, and decision-making skills. Production environments often require quick judgment when facing bottlenecks, equipment malfunction, or quality deviations. These tests measure whether candidates can diagnose problems and respond efficiently without compromising safety or output.

Safety Awareness Assessments

Safety is central to manufacturing. These assessments measure understanding of safety procedures, PPE usage, hazard detection, lockout-tagout rules, emergency response procedures, and contamination prevention. Candidates with strong safety awareness help reduce workplace accidents and maintain compliance with established standards.

Quality Inspection and Accuracy Tests

Quality accuracy tests evaluate a candidate’s ability to detect defects, maintain precision, read measurement tools, and follow QC protocols. These assessments simulate inspection tasks to ensure candidates can identify deviations quickly, reducing rework time and improving first-pass yield.

Physical Ability Tests

These tests measure physical stamina, coordination, dexterity, and ability to perform repetitive motions. They replicate real production tasks such as lifting, assembly, retrieving materials, or operating tools. Physical ability tests help ensure candidates can safely and consistently perform manual tasks during their shifts.

Production Operator Assessment Test

Designed specifically for operator-level roles, these tests measure understanding of production cycles, machine setup basics, documentation accuracy, response to alarms, adherence to SOPs, and shift productivity readiness. Operator roles demand high consistency and reliability, making this assessment crucial for screening.

Benefits of Production Assessment Tests

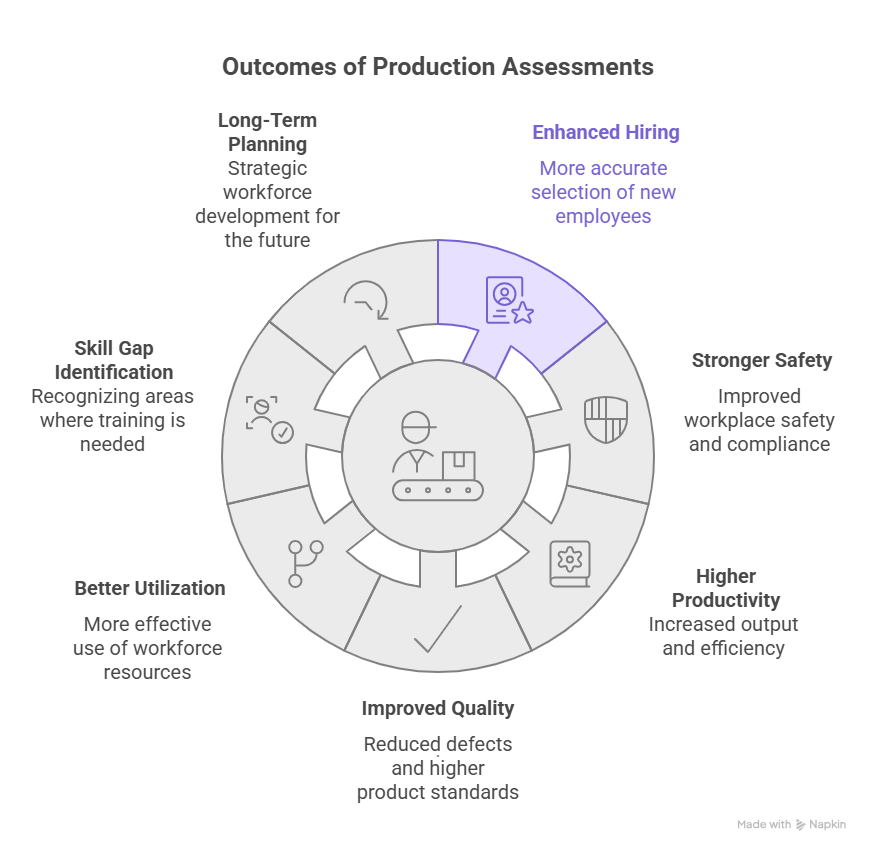

Enhanced Hiring Precision

Production assessment tests create accurate benchmarks that help organizations identify genuinely skilled candidates. Instead of relying on interviews, employers use real competency measurements to evaluate mechanical reasoning, safety behavior, and hands-on ability. This ensures hires match job expectations from day one, leading to stronger workforce stability and fewer bad hires.

Stronger Safety Compliance and Hazard Reduction

Safety assessments empower organizations to identify individuals who naturally follow rules, detect risks, and prioritize safety in their daily tasks. This reduces accident rates, protects equipment, and lowers insurance liabilities. With stricter safety regulations across manufacturing industries, production tests act as the first layer of defense against non-compliance.

Higher Productivity and Consistent Output

Candidates who perform well in production assessment tests typically demonstrate stronger situational awareness, faster learning curves, and fewer errors. This translates directly into higher productivity, smoother shift operations, predictable output, and reduced downtime. Consistency is vital in high-volume production, and assessment tests ensure employees can maintain performance standards over time.

Improved Quality Standards and Reduced Rework

Assessments that measure inspection accuracy, defect detection, and adherence to quality benchmarks help organizations hire individuals who contribute to higher product reliability. Reducing rework and scrap not only improves production costs but also enhances customer satisfaction and reputation.

Better Workforce Utilization and Team Optimization

Production tests help managers identify strengths and limitations across the workforce. This allows intelligent allocation of tasks based on skill level. Employees who excel in precision tasks can be placed in inspection roles, while those with strong dexterity may be assigned to assembly. Better alignment increases team efficiency and reduces skill mismatches.

Identification of Training Needs and Skill Gaps

Regular assessment allows organizations to track employee development, detect performance issues early, and plan targeted upskilling programs. Instead of offering generic training, companies can tailor learning interventions that address specific gaps, improving ROI on training initiatives.

Long-Term Workforce Planning

Manufacturers aiming to build multi-skilled or multi-machine operators can use production testing to identify workers with growth potential. It helps create structured career paths, support internal promotions, and build a resilient workforce capable of handling future technological shifts.

Real-World Use Cases

Automotive Assembly Operations

A leading automotive manufacturer introduced production assessment tests to improve assembly-line consistency. Before implementing these tests, high rework rates and machine handling errors were affecting throughput. After evaluating torque accuracy, tool handling skills, and component identification ability, the company hired more qualified operators and reduced assembly errors by 35 percent. Production cycle time improved, and warranty claims dropped significantly due to better product quality.

Electronics Manufacturing

In electronics production, attention to detail is mission-critical. An electronics company adopted manufacturing assessment tests to evaluate fine motor coordination, soldering precision, PCB handling skills, and visual inspection accuracy. Candidates who performed poorly were identified early, reducing the likelihood of defects in micro-components. This improved first-pass yield and significantly lowered rework and scrap costs.

Food Processing Units

A food processing company applied production operator assessment tests to evaluate hygiene compliance, food handling knowledge, contamination prevention, and packaging accuracy. By filtering candidates based on their understanding of sanitation protocols and consistency in packaging tasks, the company improved safety compliance and reduced spoiled batches. The testing process also helped standardize training for new hires.

How Skillrobo Supports Production Assessment Tests

Skillrobo provides an automated and customizable platform that helps manufacturers conduct production testing with accuracy and ease. It offers pre-designed templates for mechanical aptitude, safety protocols, assembly tasks, and machine-handling assessments. Employers can tailor tests to match specific production lines or job roles, ensuring relevance and clarity.

Skillrobo eliminates manual scoring with automated evaluation tools that deliver instant results and analytics dashboards. Managers gain real-time insights into candidate readiness, comparing skill levels across applicants and identifying the top performers quickly. The platform integrates seamlessly with HRMS systems for smoother onboarding and allows remote or on-site testing based on organizational needs.

With secure testing environments, detailed reports, and role-based competency frameworks, Skillrobo enhances hiring accuracy, reduces bias, and supports organizations in building highly capable production teams.

Wrapping Up

Production assessment tests are essential tools for manufacturers aiming to hire skilled, reliable, and safety-conscious workers. These assessments go beyond basic interviews and provide real evidence of a candidate’s job readiness, helping organizations reduce risks, maintain quality, and strengthen operational efficiency. By using structured, practical tests, companies ensure their workforce is prepared for the demands of modern, technology-driven production environments.

Skillrobo elevates this process through automation, customization, and data-driven insights. It enables manufacturing teams to evaluate candidates quickly, accurately, and fairly. With Skillrobo’s production testing capabilities, organizations can build stronger teams, reduce turnover, and ensure every hire adds measurable value to their production workflows.

FAQs

What Are Production Assessment Tests?

Production assessment tests measure a candidate’s practical skills, safety awareness, physical ability, and problem-solving capability needed for production and manufacturing roles.

Why Are Production Tests Important in Manufacturing?

They help organizations ensure candidates can perform tasks safely and accurately, reducing operational risks, quality failures, and training time.

What Is Included in a Production Operator Assessment Test?

These tests include safety evaluations, equipment handling tasks, documentation skills, SOP adherence, and basic troubleshooting exercises.

How Do Manufacturing Assessment Tests Work?

They use simulations, hands-on tasks, technical questions, and cognitive assessments to measure real-world job performance capabilities.

Can Skillrobo Help Conduct Production Testing?

Yes, Skillrobo provides customizable assessment templates, automated scoring, analytics, and secure testing environments ideal for production and manufacturing roles.